Research and development has long been an expensive element of the auto industry. For decades devising even the smallest addition to an engine could cost millions of dollars and take as long as eight months to accomplish. But thanks to advances in technology over the last five years, engineers can now test dozens of designs within a virtual environment. As a result, automakers are at last seeking affordable innovations in fuel efficiency and overall vehicle performance.

Research and development has long been an expensive element of the auto industry. For decades devising even the smallest addition to an engine could cost millions of dollars and take as long as eight months to accomplish. But thanks to advances in technology over the last five years, engineers can now test dozens of designs within a virtual environment. As a result, automakers are at last seeking affordable innovations in fuel efficiency and overall vehicle performance.

For instance, in 2010 Ford was nearly ready to roll out the latest edition of its bestselling Explorer model. However, a problem with the vehicle’s brake rotor threatened to push back the launch until a replacement could be made. While this could have taken months to do just a few years before, Ford engineers were able to design, test and manufacture a new rotor within a week. The company’s high-powered software allows them to create the most efficient design possible, which is then altered to factor in manufacturing constraints. With a price tag of only a few thousand dollars, the process allows automakers to take chances on designs that they could never have realized previously.

One of those new designs includes a 1.5-liter engine that will be introduced in China later this year. This small, fuel-efficient engine will allow drivers to avoid expensive taxes on larger engines without sacrificing performance. In fact, carmakers will face similar restrictions in the American market once regulations requiring vehicles to double in fuel efficiency goes into effect in 2025. Simulating the R&D process will allow Detroit manufacturers to experiment with a number of designs. Free of their reliance on physical prototypes, carmakers can now run their vehicles through situations where they encounter extreme cold, intense heat and other environments. The software also allows engineers to crash cars repeatedly in order to judge their safety standards. All these high-tech features require substantial computing power, which Ford houses in several multi-story buildings packed with machines. Expect big things in the future from Detroit if their technology can stay ahead of the curve.

Questions:

- Outside of obvious cost savings, what’s another key benefit of R&D simulation?

- How will R&D simulations help in meeting the needs of emerging markets?

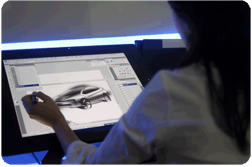

Source: Mike Ramsey, “Car-Part Designers Step on the Gas,” The Wall Street Journal, October 21, 2013. Photo by DBoyfotopages.